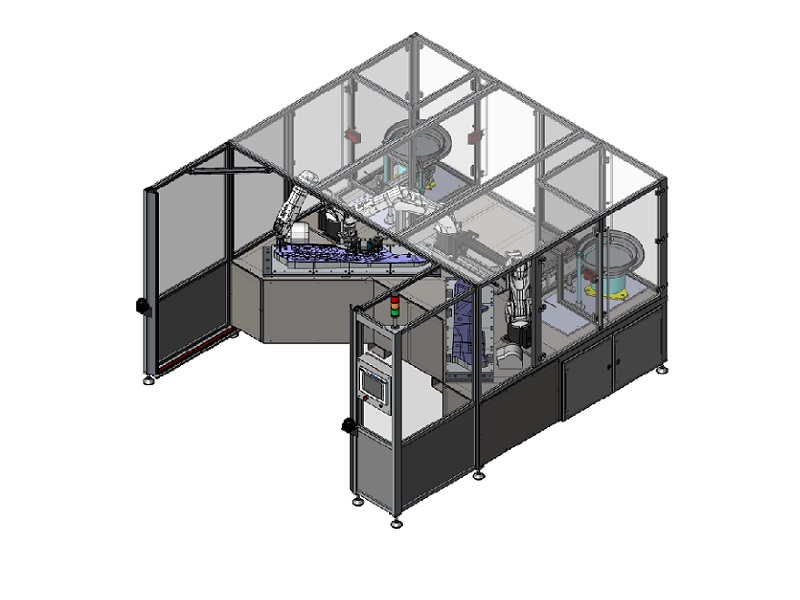

Part Presentation Solutions

- Feeding Systems

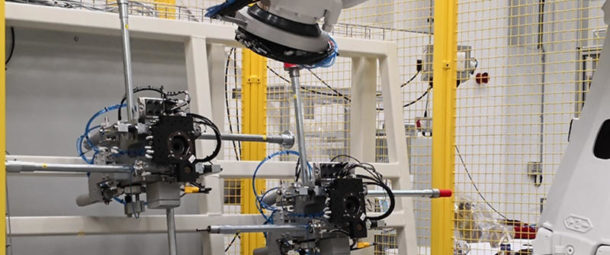

- Jigs

- Trays

- Boxes & pallets

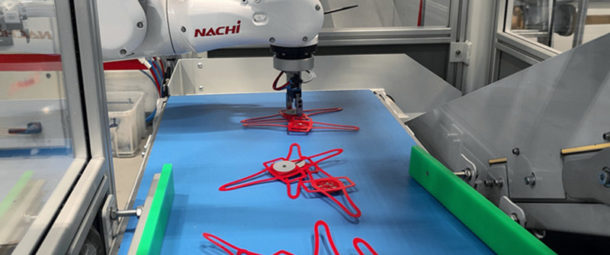

- Vision systems

- Conveyor belts

- 3-Axis Vibration Platforms

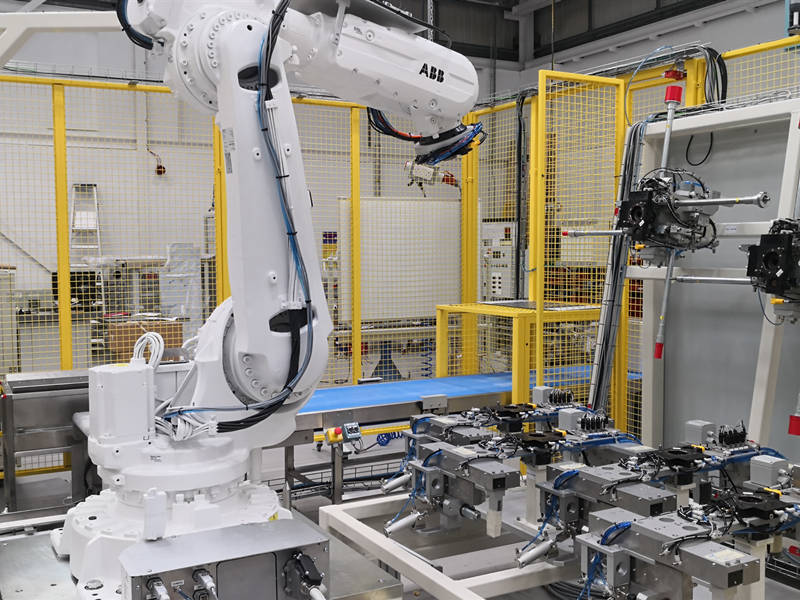

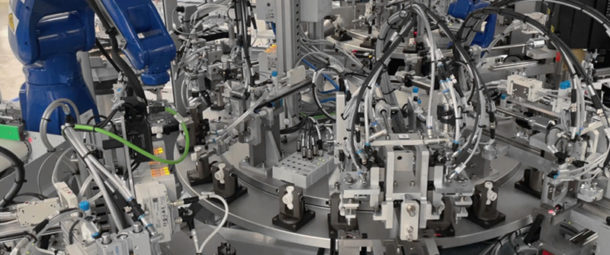

Types of robot APL use

- 6/7 Axis

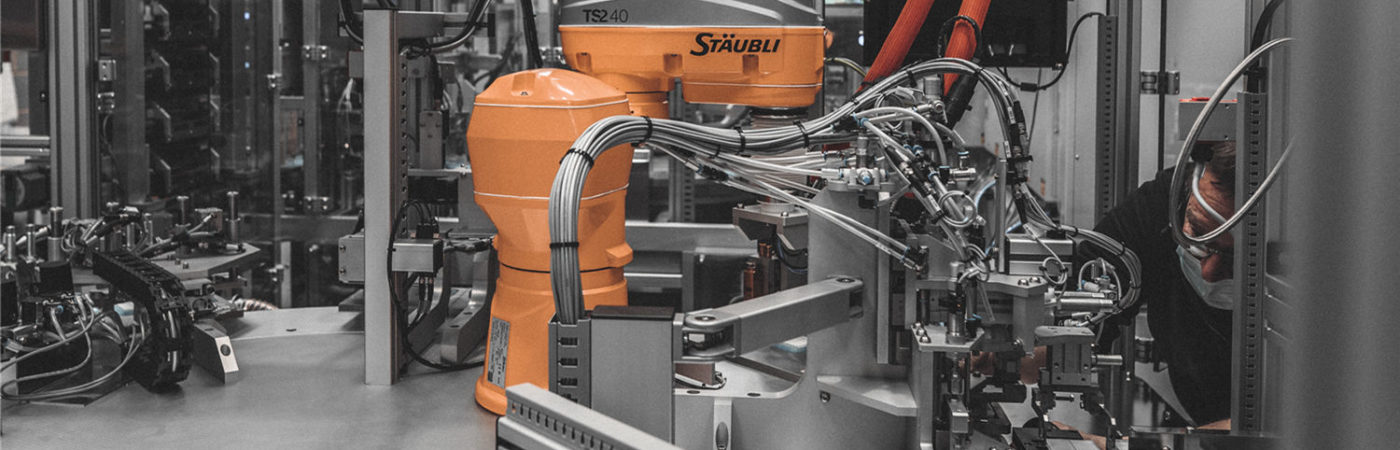

- SCARA

- Vision Guided

- Collaborative

End-of-Arm tooling

- Standard grippers & Custom designed grippers to suit any robot type

- Mechanical & Vacuum gripping systems to suit individual application

- Quick release grippers to minimize changeover time

- Fully automated gripper change systems

- Gripper components

Robot Integration & Programming

APL has wide experience in the integration and programming of robotic automation systems. Robot integration and programming experience on most major robots suppliers, including TM Robot, Fanuc, Kawasaki, Kuka, Nachi, Motoman, Epson, Mitsubishi, Stäubli, ABB, Universal Robots, and more.