Capabilities

Turnkey Manufacturing Solutions – APL provides a full turnkey package including design, manufacture, software, installation and commissioning.

Proof of Principle

An effective study provides fast, reliable informed data about the feasibility of a solution, its order of magnitude cost, process reliability and robustness with indicative cycle time information. By working closely with our customers, we evaluate the feasibility of your project and propose solutions to ensure you make right investment decisions at minimum risk.

Electrical Design

APL have an in-house electrical engineering team working in conjunction with the Mechanical Design and Controls Departments to deliver turnkey manufacturing solutions. We design, build and test the development and installation of electromechanical systems including power distribution, control panels and circuitry, safety systems and device communication protocols and architecture.

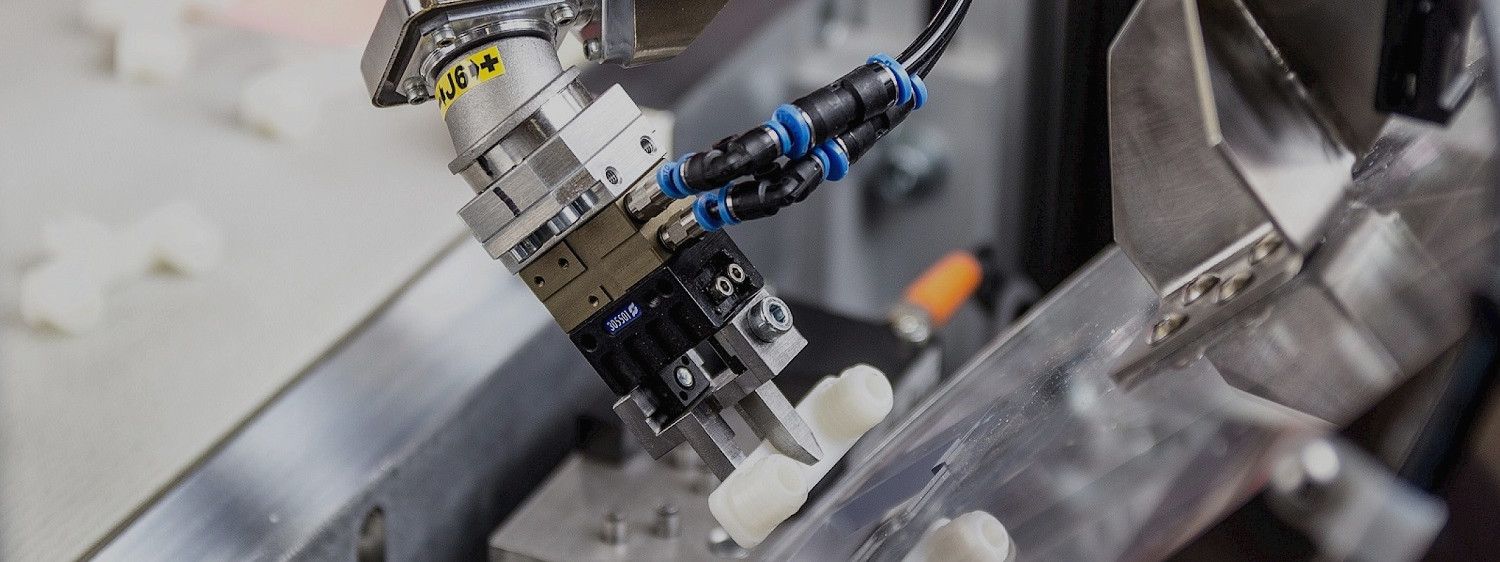

Mechanical Design

APL have built, developed and continue to retain an experienced design team that consists of some of the most knowledgeable, flexible, innovative and responsive engineers within the industry, teaming up with our customers to deliver the best in class solution.

- Mechanical Design in 3D CAD solid modeling

- Controls Design in-house, allowing the most effective integration with the mechanical features of the machine.

- Risk assessments/PFMEA’s

- Functional Design Specifications

Project Management

Your assigned APL Project Manager will ensure a holistic approach is taken on your project, managing all associated activities, including directing resource and ensuring effective cost management control.

Having practical and varying experiences within many manufacturing sectors your Project Manager will lead cross functional engineering teams to ensure that your project is delivered on time, within the agreed budget always striving to exceed where possible the customers expectations.

Software Engineering

APL’s in-house software development team has a wide range of experience in the design and build of advanced automation and robotics solutions in most manufacturing sectors. Our abilities to program over multiple platforms allow us to meet customers’ diverse needs.

Service Contracts

Once your new equipment has been installed you will want it to run during it’s life cycle just as it did when it was first purchased. Taking out a service contract with APL can make that happen.

Our experienced engineers will inspect, measure and replace where necessary any worn or faulty component(s) to keep your machine at its optimum performance level.