Feeding and Handling System for Covid-19 vaccination and testing

Feeding and Handling Systems are common but important when it comes to filling and packaging systems in the Covid-19 related product production, for example, syringes, needles and glass vials. Not only must feeding systems be built to precise and clean specifications, they also need to meet the guidelines of the Food and Drug Administration (FDA).

APL offer:

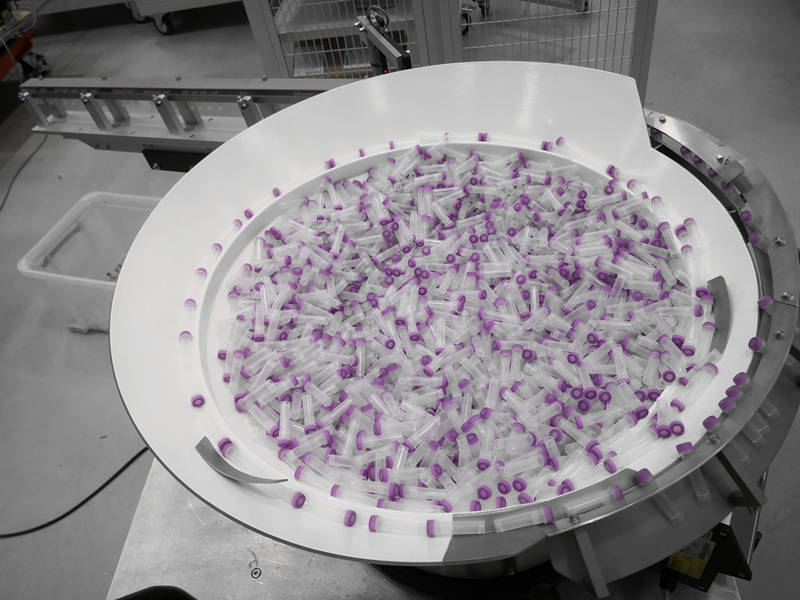

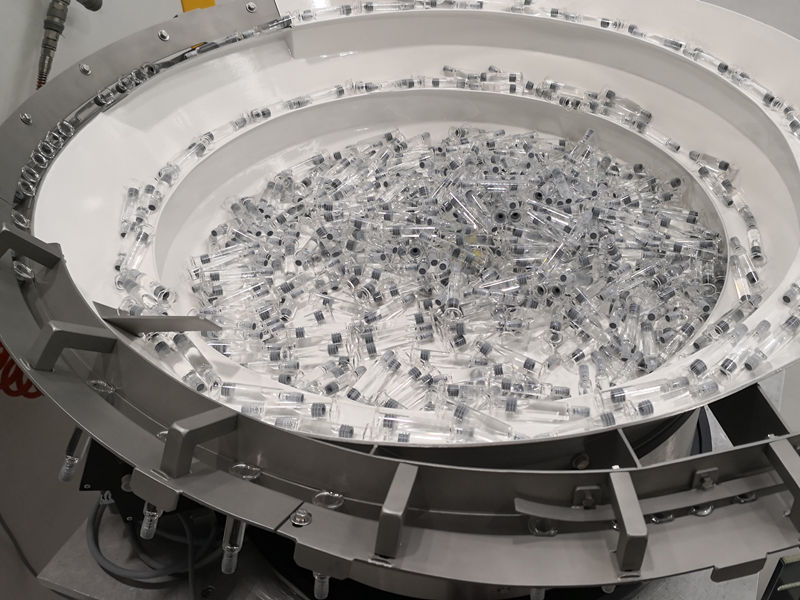

- Bowl feeder for feeding plastic vials, swabs, test tubes, syringes plungers and glass syringes

- Pharmaceutical feeder developed with GAMP Pharmaceutical standards (High-grade 316L Stainless steel)

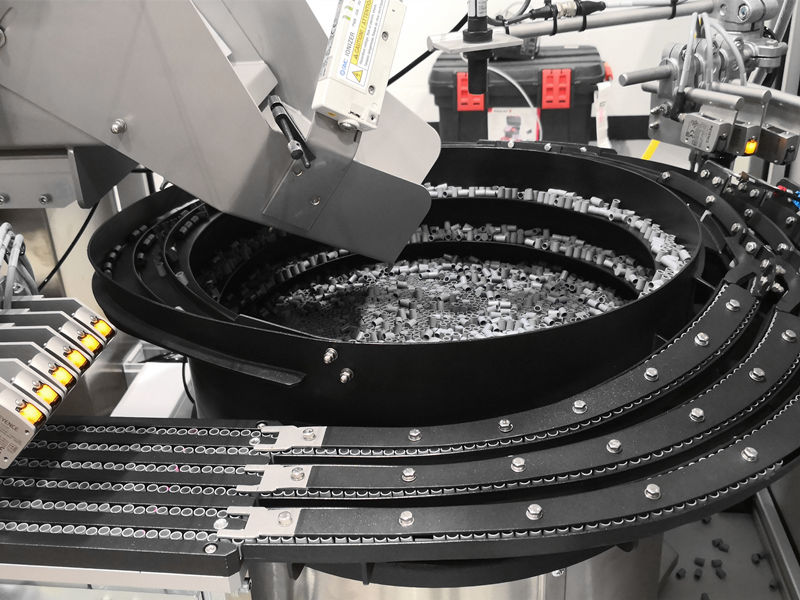

- Multi-lane feeding system that provides a consistent feed at a higher output rate to accommodate high demand

- Quick release feeder that provides a low cost option for machinery needing rapid changeover between products

- Flexible feeder for feeding of dimensional and quantity variations

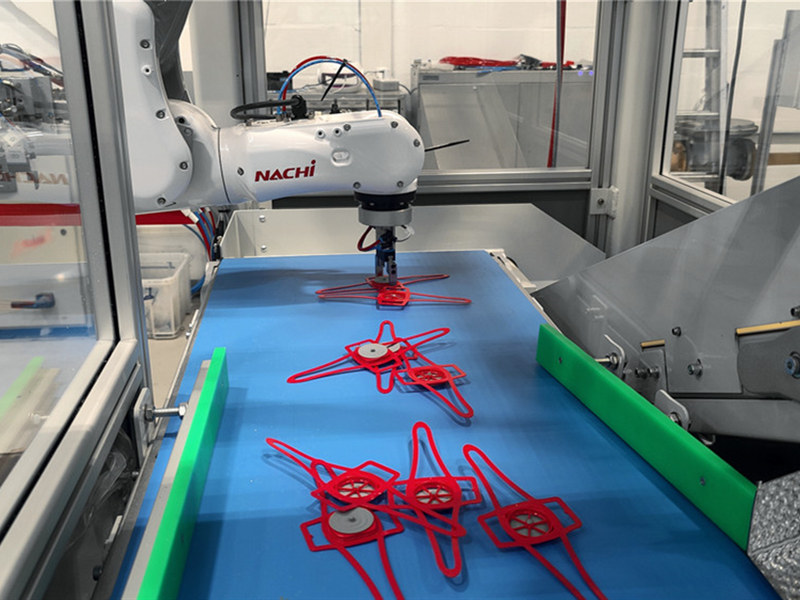

- Vision guided robotic system

APL automated feeding and handling systems help diagnostics manufacturers accelerate and enhance the production process of the COVID-19 related products.

Applications

Automated Feeding System for Covid-19

Test Tubes

Read more

Glass Vials

Read more

Multi-lane system design

Read more

Typhoon valve seat with Springfit™ disposable mask skeleton

Read more

Glass Syringes

Read more

Multi-lane vibratory bowl Feeder

Read more