The Solution

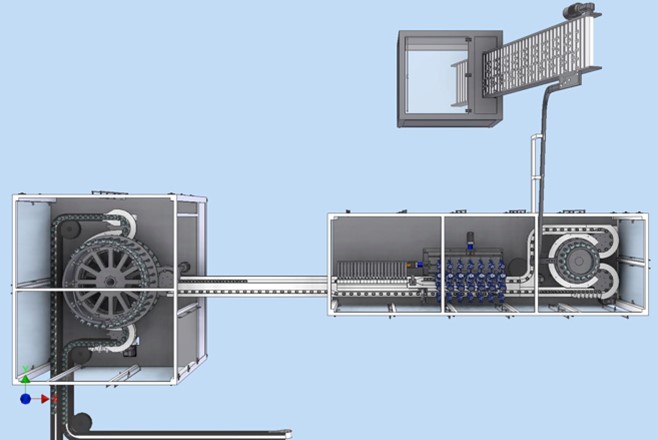

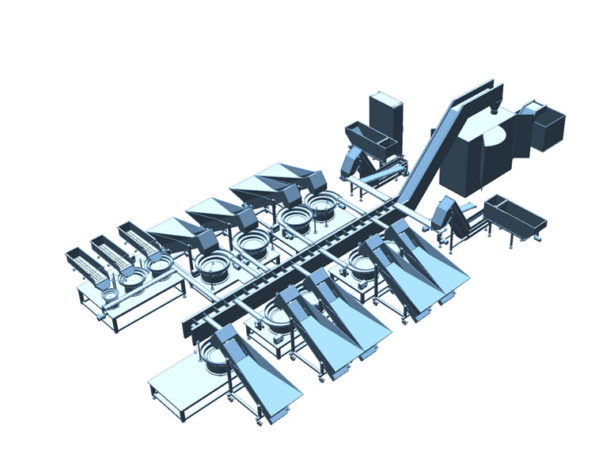

The automated solution is based on two bespoke modules integrated to form a turnkey system.

The first module applies a two part adhesive to the widget, and the second module assembles the glued widget into the can. The minimum cycle requirement is to produce 250 cans per minute.

Adhesive Dispensing Module

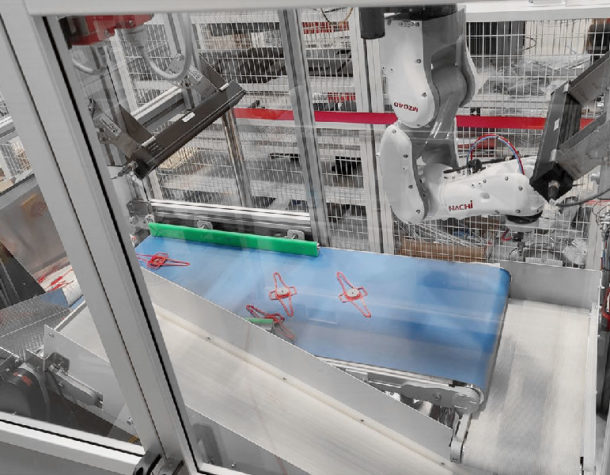

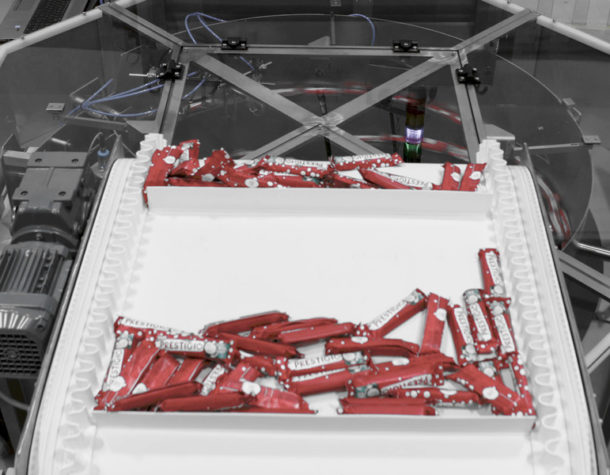

Widgets are fed from bulk into a hopper for orientation and discharge onto a gravity feed system. The orientated parts are then be placed into a small carrier via a star wheel for transfer around the adhesive dispensing module.

The carriers travels on a Slat chain conveyor where they are directed into one of two lanes to collate into a twenty one part line. A buffer sensor speeds up and slows down the widget to carrier machine on demand.

To ensure no contamination prior to adhesive application, the adhesive application is best carried out immediately after plasma treatment. Our revised concept now combines the two processes into one unit. The Plasma treatment and adhesive application will be carried out by a servo driven seven head X-Y slide unit. This carries out three cycles to plasma treat and apply adhesive to twenty one parts in a single row of carriers.

Whilst the first line of twenty one carriers is being processed the other line is released to travel through the inspection station which looks for any dispensing rejects. A new line of twenty one carriers enters the lane for processing when the dispensing cycle is complete.

Reject carriers are pushed onto a return conveyor where the reject assemblies are removed and the empty carrier re-joins the main line.

Included in the Adhesive Dispensing Module:

Rotary Assembly Module

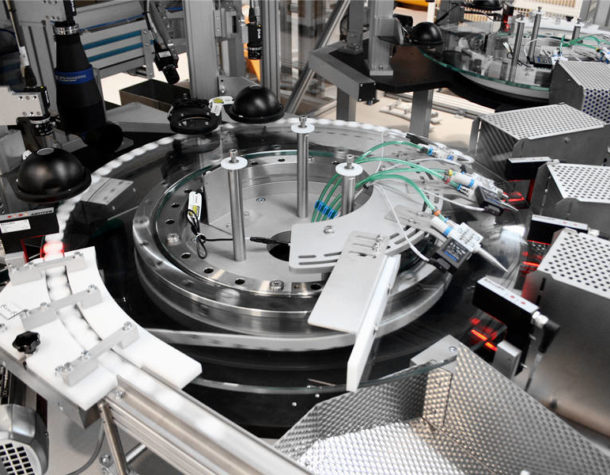

The process starts with a pre-glued and inspected widget being presented to the Assembly module in a carrier on the Slat chain out-feed conveyor from the adhesive dispensing module. The carriers are fed onto a star-wheel driven from the main table which separates the widget from the carrier and present them to a gripper finger on the main cam-driven rotary table.

As the fingers travel around they are turned through 180deg to present the widgets in the correct orientation for assembly. Inspected Cans are fed into the rotary assembly module at a lower level sitting on the closed end. They are merged by the aid of a scroll drive into the star wheel. Orientated widgets are then pushed into the can base by cam driven actuators during rotation of the table. Completed assemblies are out fed onto a Slat chain conveyor.

Included in the Rotary Assembly Module:

APL Skills

Machine building and integration, machine and process control, Poka Yoke in manufacturing, Assembly & Testing, Vision Inspection & Quality Control, Project management