Standard & Bespoke Range

Key Benefits

Applications

Enquiry Form

Scroll

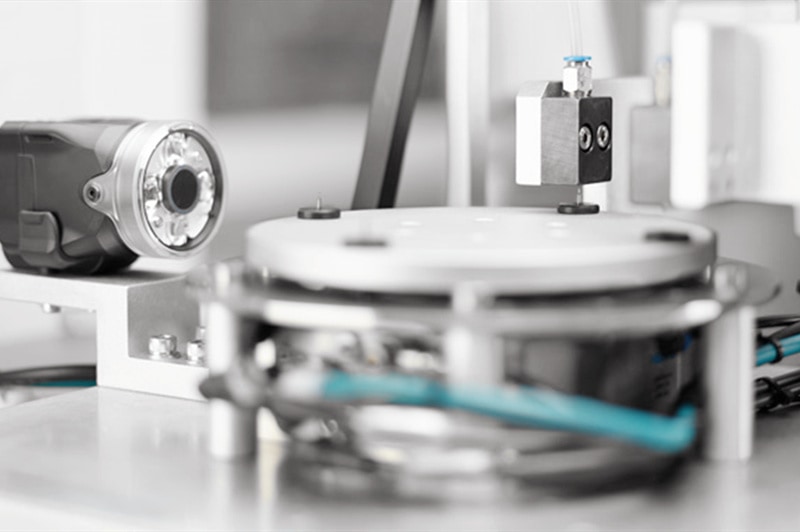

Vision System Integration

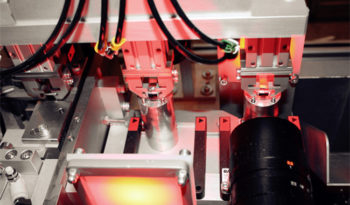

High Speed Inspection, Identification, Measurement & Tracking, Vision Guided Robotics

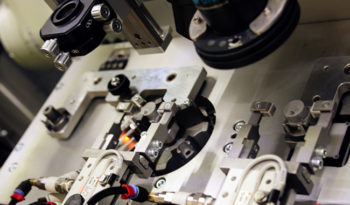

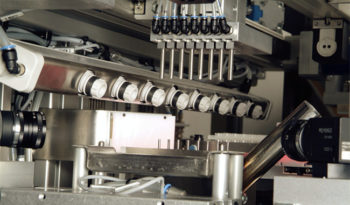

The systems have been developed to meet high speed quality control requirements for 100% inspection. Our experience with handling systems is key to offering a total solution when integrating vision software. Typical projects start with an evaluation of the vision parameters in order to provide a complete turnkey solution.

Inspection & Vision System Integration

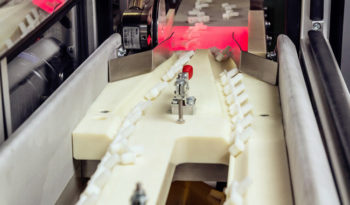

- High Speed Inspection

- Optical Character Recognition

- Special Purpose Vision Machines

- Vision Integration

- Image Processing Equipment

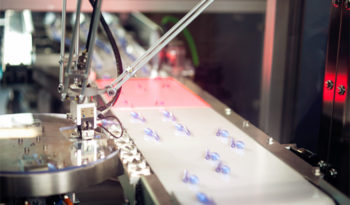

- Vision Guided Robotic Systems

- Code Reading

- Optical Sorting & Orientating

- Test & Measurement

- Automated Quality Inspection

- Poka-Yoke System

…and more!

Products

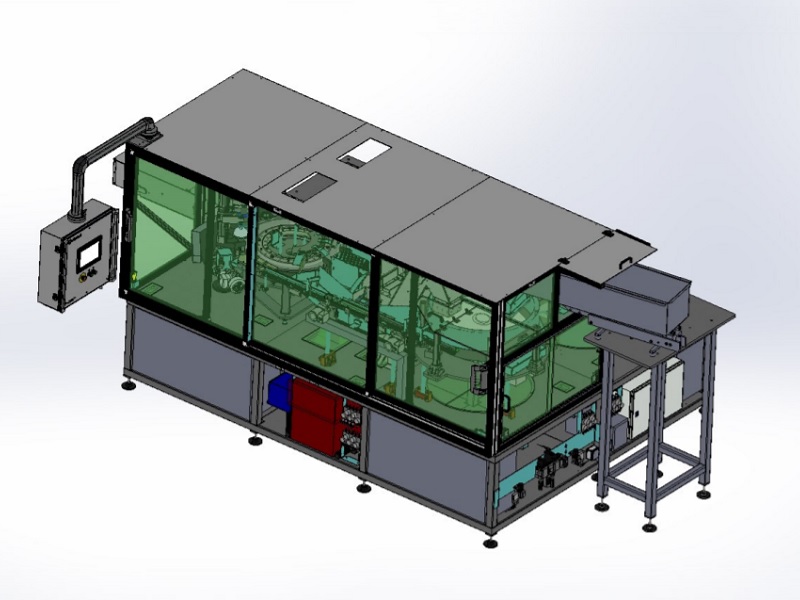

Standard and Bespoke Vision Systems

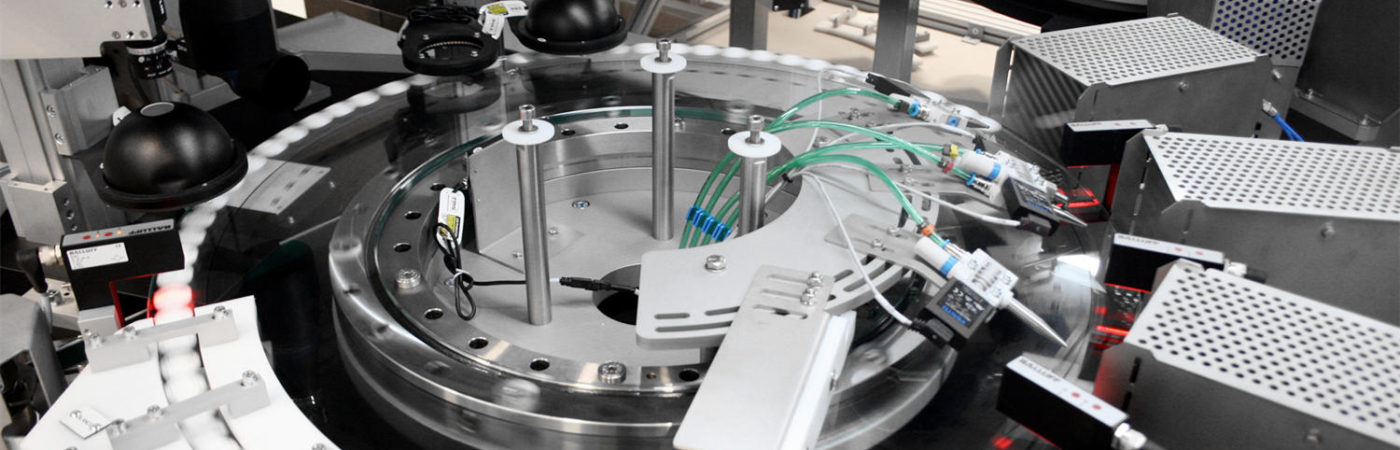

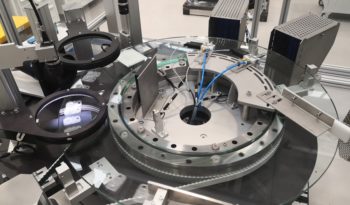

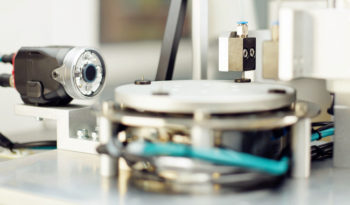

Standard Platform: MK360™ Glass Disc Vision Machine

Read more

Presence Verification

Read more

Flaw Detection

Read more

Surface Inspection

Read more

Code Reading

Read more

End of Line Inspection

Read more

Vision Guided Robots

Read more

Quality Control Inspection

Read more

Test & Measurement

Read more

OCR

Read more

Key Benefits

High speed Camera Inspection

360° inspection

100% quality control

100% End of line inspection

Solutions

Applications

×

Contact

Have an enquiry? Call us on +44 (0) 12028 62900 or Quick Contact

"*" indicates required fields

Read our Privacy Policy to learn how we manage and protect your submitted information.