The Solution

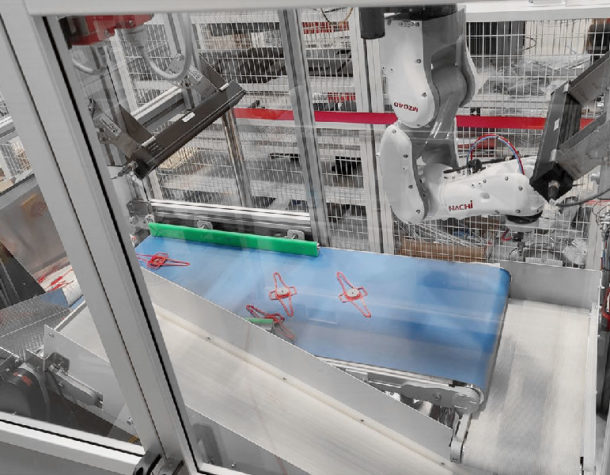

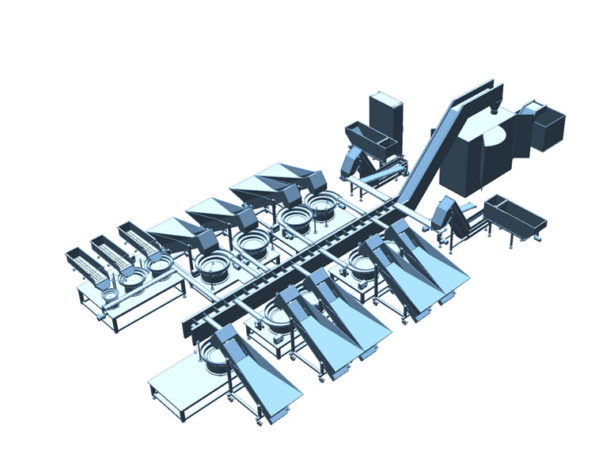

The automation solution consisted of 2 6-axis robots for clip presentation and insertion, one welding robot with ultrasonic welding head, 2 bowl feeding systems and 2 printers.

The robot clipping and welding system has independent right and left hand stations, each including a mirrored assembly fixture for a left hand or right hand automotive panel.

Product

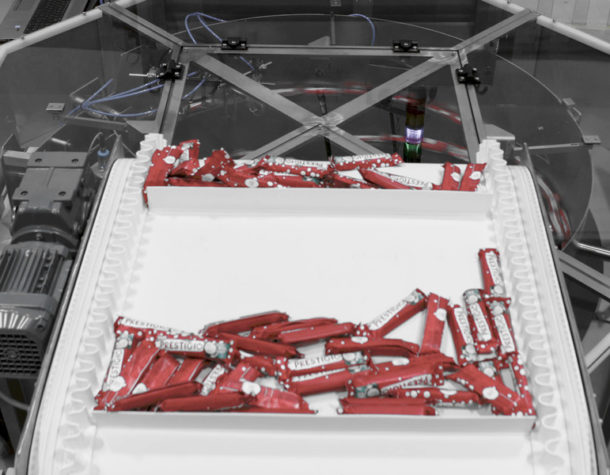

Side Panels LHD & RHD, each panel having 14 clips 28 clips in total

Performance

Total cycle 100 seconds

The system consists of:

- Welding robot

- Clip insertion robot

- Telsonic Ultra-Sonic welding head and horn

- Steel fabricated frame with Lexan panels and interlocked doors for access

- Manually operated table

- Back up clip magazine

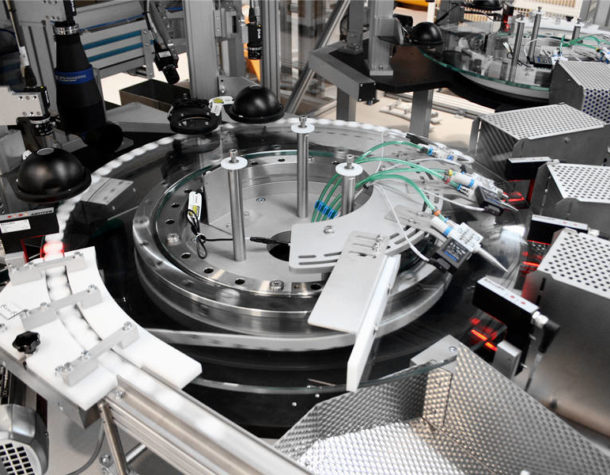

- Bowl feeder system with escapement for robot pick up

- System Control via the robot

APL Skills

Machine building and integration, machine and process control, Robot integration, Bowl Feeding, Robot welding system, Robotic assembly system, Project management