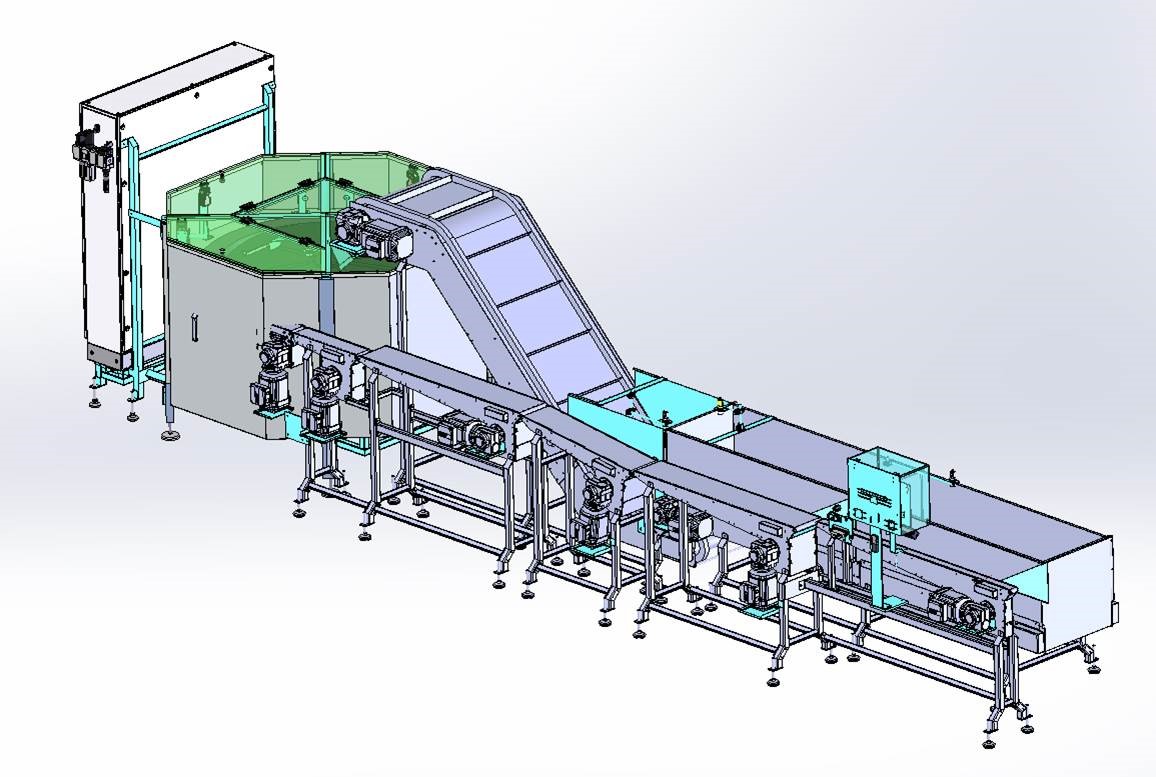

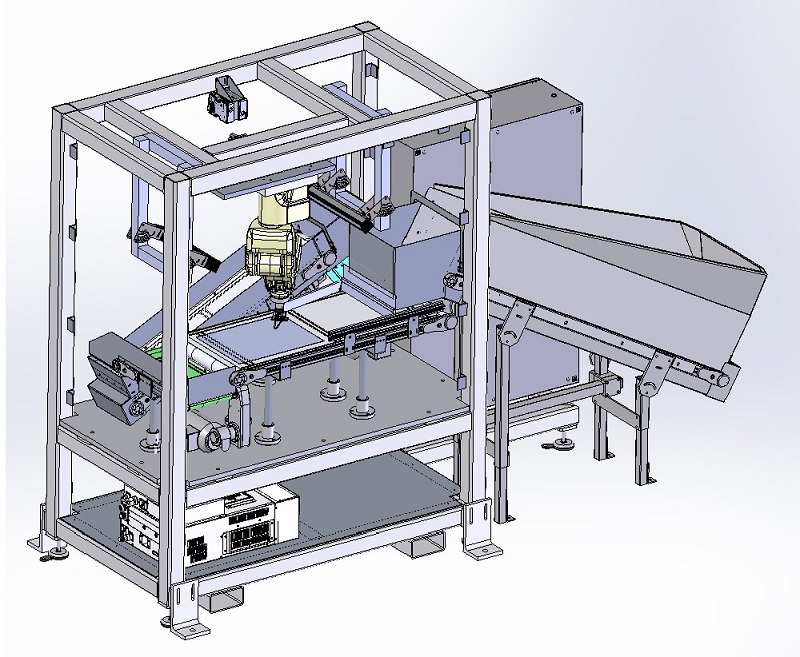

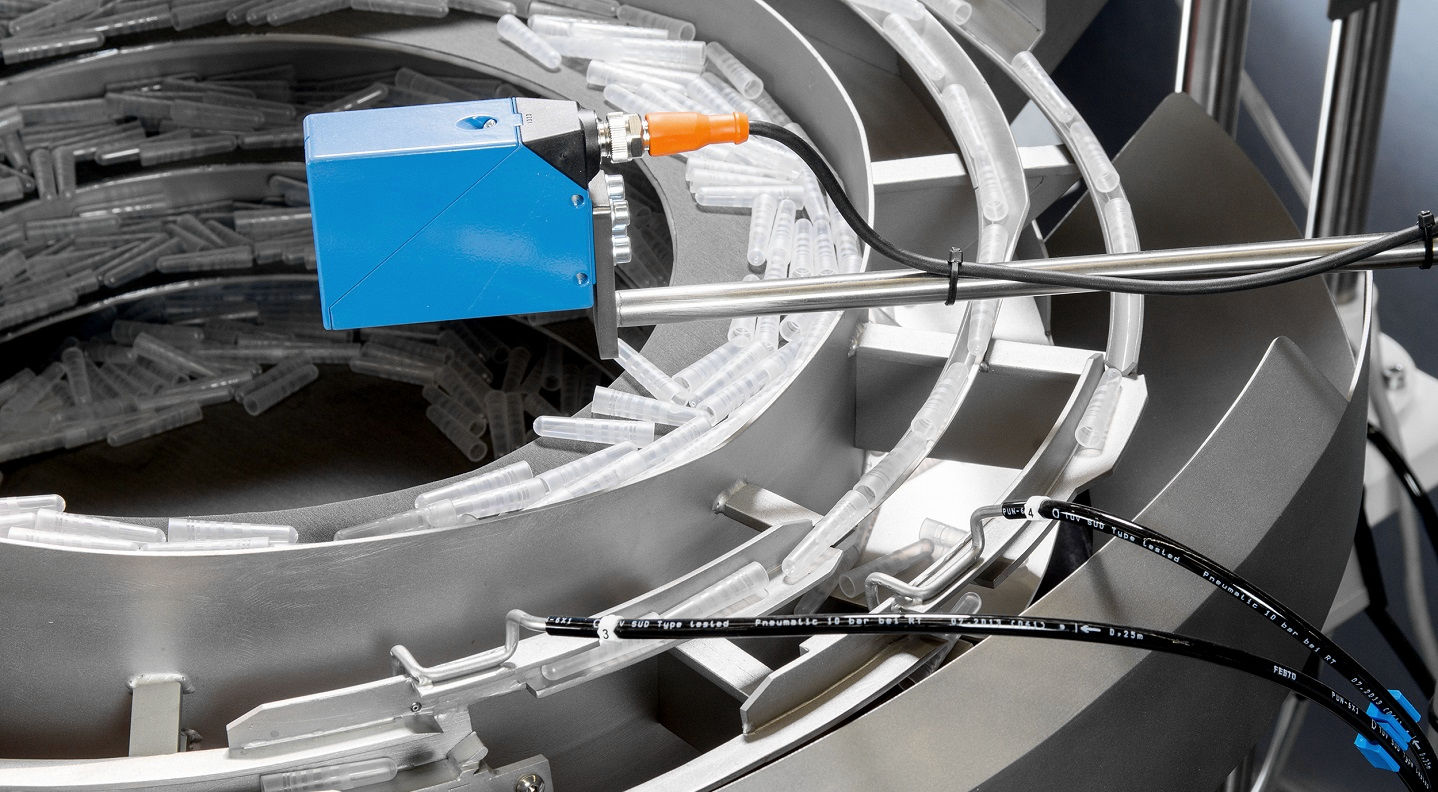

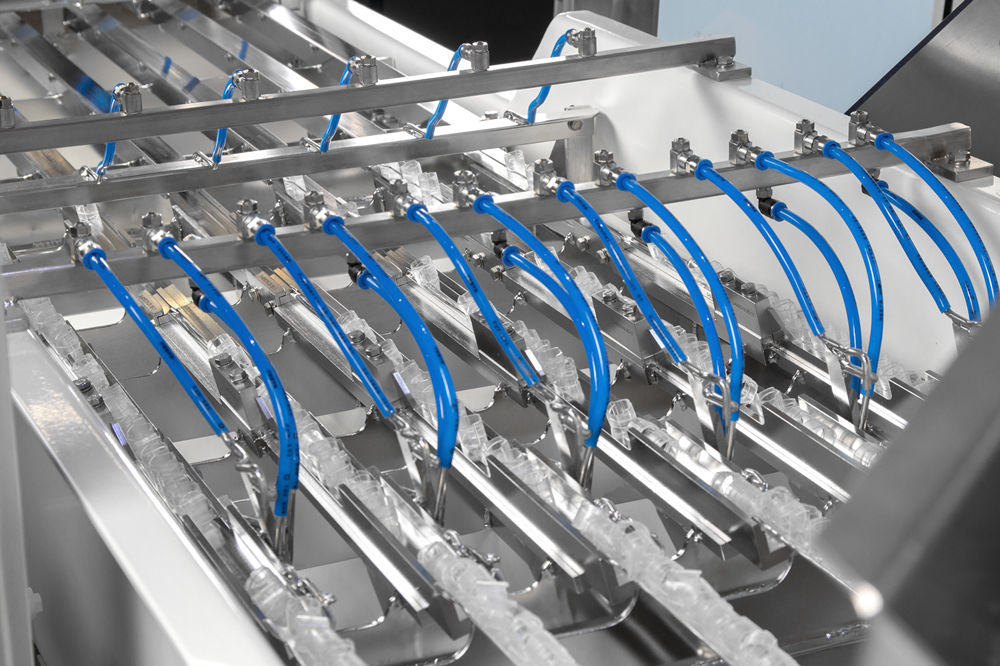

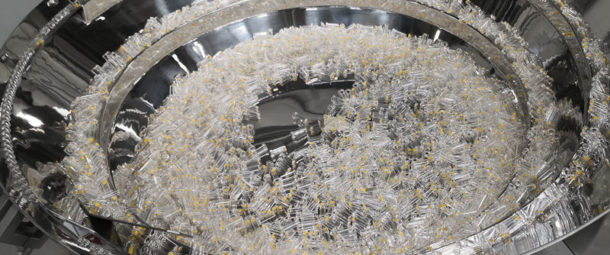

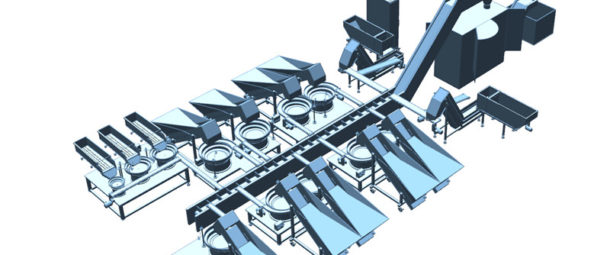

All equipment is manufactured to the highest standards of quality upon which we have built our reputation. UL/CSA Approved. Our product range is manufactured to meet the highest demands of the food and pharmaceutical industries and also includes equipment manufactured to UL and CSA standards.

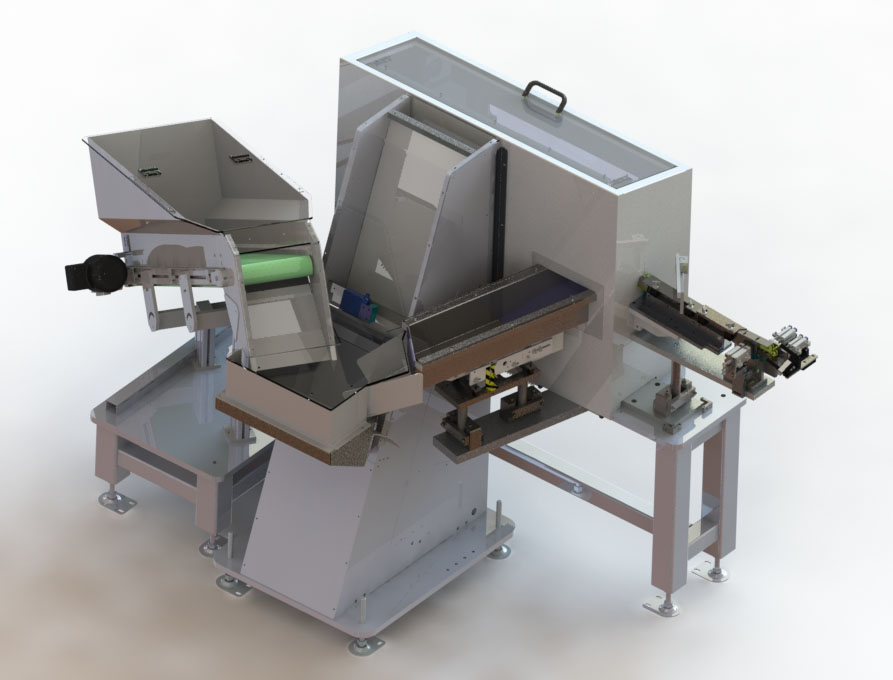

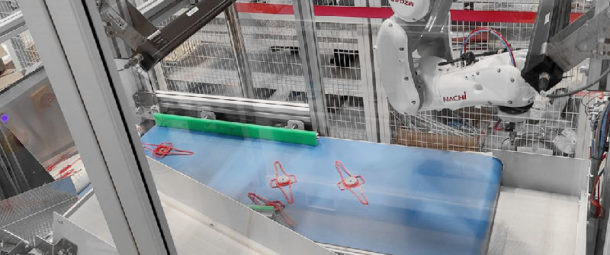

With many years experience in the automation and parts handling industry we have earned a reputation for the most robust and reliable equipment on the market. We provide an extensive range of the most efficient drive units, controllers and accessories for either standard or special requirements.